Industrial Spot Repairs

Spot Repair Lining - Saves Time and Money

Request Info Here!

Have You Inspected Your Pipeline and You Only Have a Localized Area To Repair?

Have you been recently experiencing some flooding issues in nearby areas?

You decide to investigate your pipelines only to discover the source of the issue.

You noticed that one section of your pipeline is severely damaged, but other than that, the rest of it seems to be in good condition.

Do you really want to spend money replacing an entire pipeline for one small section?

You Might Need A Spot Repair

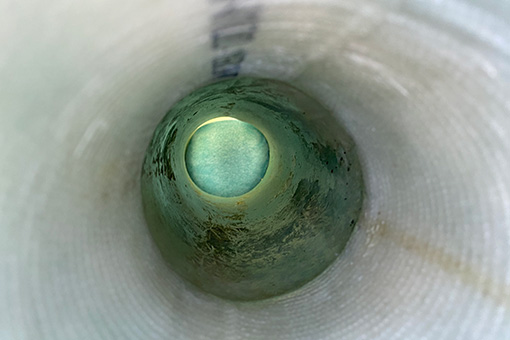

An Industrial spot repair is a trenchless repair that only requires fixing one section of the pipe as compared to the entire pipe in an Industrial application.

These small, damaged pipes can cause a lot of flooding in a plant and can be costly to shut the operation down due to a leaking pipeline. However, the traditional dig-and-replace method would be unnecessary and costly in this situation.

The next predicament that you'll find yourself in is figuring out exactly how you'll be able to replace this small pipe section. You can contact InnerCure® Technologies and we will connect you with a trained installer.

View Product Page

Structural Rehabilitation - Able to Repair Bends and Elbows

Repairs Only the Area That is Damaged

Less Expensive Than Excavation

Usually Repairs can be Completed in Minutes

Not Necessary to Line the Whole Line Section if You Have a Localized Problem

Economical Solution

Stops Water Intrusion or Exfiltration in a Localized Area

InnerCure® Technologies, Inc. Provides Training and Materials

InnerCure® Technologies, Inc. Technical Advisors have the knowledge to advise and train on how to install InnerCure®'s Spot Repair System. Our professionals can offer the proper equipment in order to conduct this procedure safely and effectively.

We recommend a clean and unobstructed video inspection. This requires a high resolution camera that is initially inserted through the pipeline to locate the damaged area. Once the location of the repair area is identified, drain cleaning will be conducted to prepare the pipeline for a repair. In certain circumstances cleaning maybe required prior to the television inspection. After the pipeline has been prepared for the installation, the InnerCure® Spot repair material is loaded onto the packer and delivered to the location needing repair. Depending on the materials selected, within a few hours or less you will have a structural repair installed and flowing water without having to line or replace an entire pipeline section. For more information about our municipal spot repair services, please give us a call at (844) 748-5200.

Get Expert Project Advice

Please provide your information via this online form and someone will contact you regarding best options based on the specific needs of your project. If you should need more urgent service please don't hesitate to call us at (844) 748-5200.

Become a Certified Installer

Please complete this online form to receive additional information in how to become a certified Cured-in-Place Pipe (CIPP) installer in your area. We offer ambient, heat or UV Cured spot repair technology. You can also call to speak to one of our Technical Advisors at (844) 748-5200.